Body Butter Base

- Free UK Shipping - Orders Over £25

- Worldwide shipping

- Carbon neutral

- Secure payments

- In stock, ready to ship

- Backordered, shipping soon

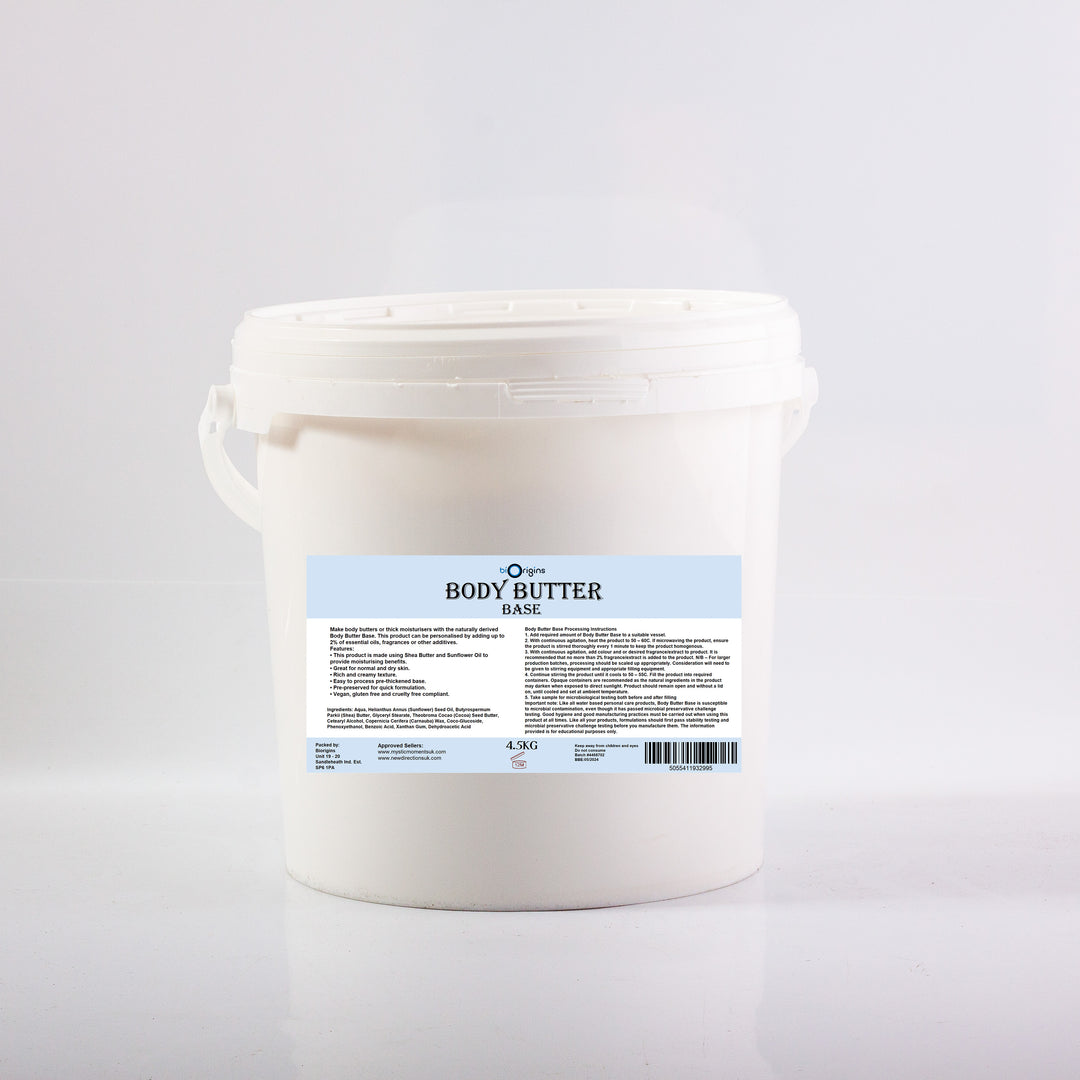

Body Butter Base

Make body butters or thick moisturisers with the naturally derived Body Butter Base. This product can be personalised by adding up to 2% of essential oils, fragrances or other additives.

Features:

• This product is made using Shea Butter and Sunflower Oil to provide moisturising benefits.

• Great for normal and dry skin.

• Rich and creamy texture.

• Easy to process pre-thickened base.

• Pre-preserved for quick formulation.

• Vegan, gluten free and cruelty free compliant.

Ingredients: Aqua, Helianthus Annus (Sunflower) Seed Oil, Butyrospermum Parkii (Shea) Butter, Glyceryl Stearate, Theobroma Cocao (Cocoa) Seed Butter, Cetearyl Alcohol, Copernicia Cerifera (Carnauba) Wax, Coco-Glucoside, Phenoxyethanol, Benzoic Acid, Xanthan Gum, Dehydroacetic Acid

Body Butter Base Processing Instructions

1. Add required amount of Body Butter Base to a suitable vessel.

2. With continuous agitation, heat the product to 50 – 60C. If microwaving the product, ensure the product is stirred thoroughly every 1 minute to keep the product homogenous.

3. With continuous agitation, add colour and or desired fragrance/extract to product. It is recommended that no more than 2% fragrance/extract is added to the product. N/B – For larger production batches, processing should be scaled up appropriately. Consideration will need to be given to stirring equipment and appropriate filling equipment.

4. Continue stirring the product until it cools to 50 – 55C. Fill the product into required containers. Opaque containers are recommended as the natural ingredients in the product may darken when exposed to direct sunlight. Product should remain open and without a lid on, until cooled and set at ambient temperature.

5. Take sample for microbiological testing both before and after filling

Important note: Like all water based personal care products, Body Butter Base is susceptible to microbial contamination, even though it has passed microbial preservative challenge testing. Good hygiene and good manufacturing practices must be carried out when using this product at all times. Like all your products, formulations should first pass stability testing and microbial preservative challenge testing before you manufacture them.

The information provided is for educational purposes only.

Specification Documents